Tough Cell is a high-performance geocell, structured in a 3D honeycomb formation of polymeric material. The Tough Cell cellular confinement system ensures equal load distribution, increases the pavement layer strength and reinforces the infill material of low strength and easily sourced aggregates such as sand, local soils or recycled materials. Tough Cell Geocells are fabricated from a new Novel Polymeric Alloy called Neoloy®; specifically developed for geocells that have been found superior in comparison to any other geocell or cellular confinement product. Tough Cell allows you to build more durable roads, while reducing up to 60% of your project’s Total Cost of Ownership (TCO).

Tough Cell strips are welded together to form a honeycomb-like polymeric cell section which are laid out and filled with granular infill, creating a reinforced composite “mattress” used for versatile soil stabilization and reinforcement applications including municipal paved and unpaved roads, access roads, heavy haul roads, mining roads, railroads, container and heavy equipment yards, slopes, channels, retaining walls and landscaping. This technology is the preferred choice in a multitude of industrial market sectors including oil and gas, logging, mining, military, and other soil reinforcement projects especially on soft soils, peats, expansive clays and permafrost.

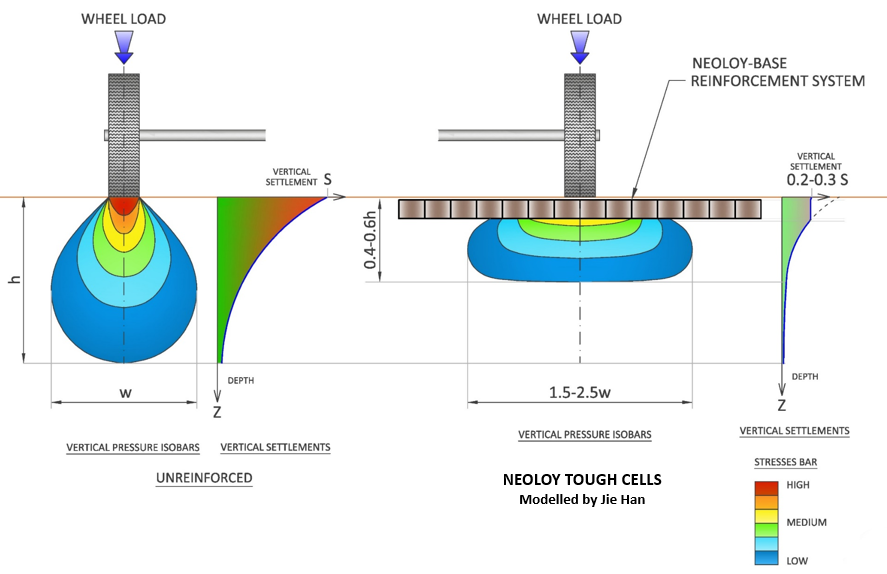

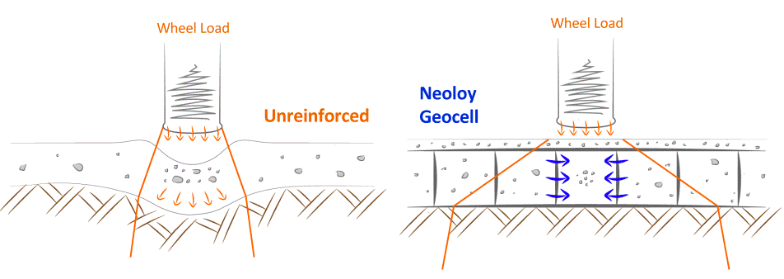

Tough Cell has a patterned structure of geocells designed to distribute vertical load upon a larger area, therefore reduce the strain on one spot and maximize the load bearing capacity of the structure This mechanism is referred to as “the beam effect”. When loading vertically on top of the geocell, a semi-rigid slab is formed over the soft soil, distributing the load evenly and decreasing the stress to the subgrade. This effect was carefully and vastly tested at the University of Kansas and the Indian Institute of Technology, Madras.

Tough Cell Beam Effect

The first cellular confinement systems were developed by the US Corps of Engineers for tactical military use. The initial 3D honeycomb grids were made from aluminum and its purpose was to distribute vertical loads and improve the bearing capacity of soft soils by using materials like the sand in beachheads as infill and create temporary passageways for military vehicles and supplies. In the late 1970’s, the aluminum was replaced by high density polyethylene (HDPE) polymer due to its relatively moderate cost and the flexibility it afforded in packaging the materials for shipment and in their deployment in the field. Road reinforcement applications required a solution with proven long-term durability, suitable for continuous heavy load stresses that are common in busy highways, railways ports and airports.

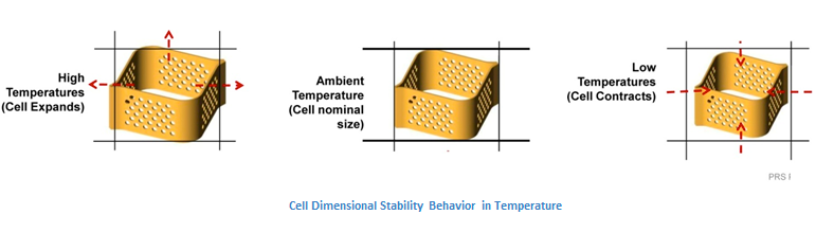

In 2005, a visionary R&D program was undertaken to compound a nano-polymeric engineering alloy to meet the long-lasting performance required for public transportation and DOT applications. The result was Neoloy®- a Novel Polymeric Alloy (NPA) of polyester/polyamide nano-fibers dispersed in a polyethylene matrix, developed to improve the long-term stiffness and Long Term Dimensional Stability (LTDS) of the geocell. Neoloy is a nano-technology material that combines the ductility of polyethylene with the stability and resistance of polyamides, manufactured under patented processes.

Cell dimensional stability behavior in temperature changes

Incorporating Geocells in Existing Pavement Design Methods

Design for geocell base reinforcement of pavements and/or subgrade stabilization is based on the resilient modulus of the pavement structures. Based on comprehensive research performed on NPA geocells, the proven values were used to establish geocell modelling and integrate them into standard Mechanistic-Empirical design methods, such as the Layered Elastic Model. This section described the design methods used for NPA geocells and published by international standard design guides, such as the Netherlands and ISO.

Modulus Improvement Factor (MIF)

The Modulus Improvement Factor (MIF) is well established by laboratory and full-scale testing, resulting in empirical validated figures. The magnitude of improvement is dependent upon the geocell geometry, properties of the geocell material, infill modulus and depth, and support of the subgrade layer (SIF). The relation of increased modulus of the base course due to geocell reinforcement vs. the conventional non-reinforced modulus is defined as a Modulus Improvement Factor (MIF), expressed in the following formula:

Confining soil in the Tough Cell honeycomb like geometry is what leads to a strong structure even when using soft soils.

Load distribution showing the effect of cellular confinement with and without Neoloy Geocell

New guideline emphasizes the key geocell properties required for road base reinforcement

This published standard in the Netherlands is an excellent example of the growing trend to create standard guidelines for the use and design of geocells worldwide. It covers the required material properties and design principles that should be adopted to optimize geosynthetic reinforcement performance for pavements – and specifically for geocells.

This Guideline was written by a team of experts for SBRCURnet(CROW), highly respected Dutch institutes that develop guidelines and standards in the fields of civil engineering, road construction, and traffic engineering.

A key point of the document is that the extent of the reinforcing or stabilising effect is determined by the material from which the geocell product is made and the geometry. The most important material properties are elastic stiffness and resistance to permanent deformation (creep). The limit on plastic deformation for reinforcement synthetics is defined as low deformation, e.g., less than 2%. The actual effectiveness of base reinforcement is reflected in the support improvement factor (SIF) and the modulus improvement factor (MIF).

Click here to view a translated summary of the guideline

(All rights reserved to SBRCURnet and CROW, NL)

Highlights of Guideline

- Elastic stiffness and resistance to permanent deformation – the most important material properties(para. 1.2.4):

“In addition to the structure of the road construction, the extent of the reinforcing or stabilising effect is determined by the material from which the product is madeand the geometry. The most important material properties are the elastic stiffness and the resistance to permanent deformation (creep)…. Materials that exhibit a lot of creep will gradually lose their reinforcing capacity over time.” - Permitted accumulated geocell deformation – below 2% (para. 1.2.4)

“…Therefore, this type of base reinforcement is only effective if the deformations are limited to, for example, 0.5%. A distortion (elongation) of the geosynthetics of 2% horizontally will lead to many centimeters of distortion vertically in the road. - Geocell key properties determine the pavement reinforcement improvement factor (para. 2.2.4):

“The geocell mechanism provides an improved spread angle through the so-called “beam effect” (see Fig. 2-6).”

Table 2.5 – Global properties of reinforcement geocells*

| Property | Unit | Testing method | Value |

| Dynamic stiffness modulus (net) (DMA-test) | MPa | EN-ISO 6721-1 ASTM E2254 | ** |

| Cumulative plastic distortion (SIM test) | % m/m | ASTM D6992 | <3 |

| Tensile force, non-perforated cell wall (wide width) | kN/m | EN-ISO 10319 | 20-29 |

| Tensile force, perforated cell wall (wide width) | kN/m | EN-ISO 10319 | 16-25 |

| UV and Oxidation resistance (High-Pressure Oxidative Induction Time (HPOIT) at 150°C | minutes | ASTM D5885 | > 400 |

* values available only for geocells with rigid cell walls

** values depend on the application

The Neoloy material in the PRS Neoloy Geocell enables a new generation of geocell, with performance properties guaranteed for the project design life:

- Elastic Stiffness (Dynamic Modulus) – maintain stiffness under dynamic loading.

- Permanent Deformation (Creep) – elongation <3% at the end of the design life

- Cell Tensile Strength – maintain geocell geometry under load

More than 55 academic papers were published over the last 10 years validating the effectiveness of Neoloy (NPA) geocells used for soil reinforcement in roads, railways, retaining walls and other geo-technical engineering applications. As a result of this comprehensive research, Neoloy-based geocells are the only geocell with a proven engineering methodology that integrates the performance characteristics with the structural engineering requirements.

Download technical specifications documents here:

- PRS NEOLOY® Tough Cell – CATEGORY B (PDF)

- PRS NEOLOY® Tough Cell – CATEGORY C (PDF)

- PRS NEOLOY® Tough Cell – CATEGORY D (PDF)

Download installation manuals documents here:

- Installation Guide – Load Support _v2019.1

- Installation Guide – Slope Protection – v2019.1

- Installation Guide – Channel Protection_v2019.1

- Installation Guide – Earth Retention – v2019.1

- Installation Guide – Geomembrane Protection – v2019.1