National Road T5 Pärnu – Rakvere – Sõmeru, Estonia

The optimized design of the T5 roundabout on the State road received the approval of the Estonian Transport Administration and contractor AS TREV-2 Grupp.

Read moreNational Road T5 Pärnu – Rakvere – Sõmeru, Estonia

THE CHALLENGE

Contractor needed cost-effective and long-term load bearing pavement for new T5 roundabout road. They found the solution together with EM Infra OÜ and used for that Neoloy Tough Cell.

CONVENTIONAL SOLUTION

Conventional construction on this road is based on removal and replacement of clay subgrade. The cost of importing replacement infill along with the installation of drainage systems proved prohibitively expensive.

Due to the requirements of the reinforced intersection the contractor would need to build four layers of asphalt.

NEOLOY TOUGH CELLS SOLUTION

Client chose Neoloy Tough Cells due to its ability to distribute vertical loads laterally and increase the bearing capacity. Neoloy Tough Cell solution gave the opportunity to eliminate clay subgrade excavation and one layer of asphalt.

The Neoloy Tough Cell solution was based on reclamation of the reusable materials. It provided maximum engineering at the lowest economic and environmental cost. Neoloy Tough Cells were filled with onsite reclaimed asphalt (RAP).

The Neoloy mattress “floats” provides a high modulus improvement factor (MIF) for asphalt surface road. This is due to Neoloy’s unique properties – low permanent deformation (<3% at 75 years); high tensile strength (>19 kN/m perforated); and high (elastic) stiffness (>525 MPa @60°C) – that create a beam (slab) effect.

The reinforced road successfully supported the traffic of heavy construction and haul vehicles in all weather conditions. Solution was cost-effective, installed quickly and environmentally friendly.

NEOLOY TOUGH CELLS DESIGN

- 15 cm – asphalt layer

- 18 cm – granular base

- 5 cm – reclaimed asphalt (RAP)

- 12 cm Neoloy Tough Cell 330-120-C filled with RAP

- 26 cm – sand subbase foundation

- Exsisting soil

BENEFITS

- Neoloy Tough Cell infilled with onsite reclaimed asphalt (RAP)

- Reduced asphalt thickness by 17%

- Fast installation reduced downtime

- Cost-effective – eliminated one layer of asphalt and new infill material

- Highly sustainable – lowers carbon footprint by reducing amount of aggregate

- Improved pavement lifespan

- Lower tensile strain at bottom of asphalt layer leads to lower fatigue, higher design lifetime

Stabilized Pavements for Biofuel Processing, Peat Subgrade, Finland

Neoloy improved the bearing capacity of soft subgrade, and created a high modulus base layer that ‘floats’ over the peat layer subject to seasonal volumetric changes.

Read moreStabilized Pavements for Biofuel Processing, Peat Subgrade, Finland

THE CHALLENGE

Vapo needed cost-effective and long-term load bearing pavements for roads and platforms for the extraction and processing a steady supply of renewable energy for domestic, municipal and industrial use. They found the solution with PRS Neoloy Tough Cells.

CONVENTIONAL SOLUTION

Conventional construction on peat bogs is based on subgrade replacement, drainage systems and large amounts of gravel. Beyond the unsustainability of hauling large amounts of gravel to remote regions, the weight of such pavement structures results in additional settlements, due to consolidation and creep.

NEOLOY TOUGH CELLS SOLUTION

Vapo chose Neoloy due to its ability to distribute vertical loads laterally and increase the bearing capacity of soft, saturated peat soil. The Neoloy mattress “floats” over the soft soil and provides a high modulus improvement factor (MIF) for the gravel or asphalt surface road and yard pavements. This is due to Neoloy’s unique properties – low permanent deformation (<3% at 75 years); high tensile strength (>19 kN/m perforated); and high (elastic) stiffness (>525 MPa @60°C) – that create a beam (slab) effect.

In addition, Neoloy performed extraordinary (or very well)in the freeze-thaw cycle of the Finnish extreme climate and was unaffected by the volumetric changes in the soil moisture. Drainage systems and soil replacement were unnecessary.

Vapo was very satisfied with both the unpaved and paved pavements, with low surface degradation reported over a 14-year period of intensive use. The surface gravel layer was recently renewed to provide many more years of heavy-duty use.

BENEFITS

- Increased operational efficiencies – of the roads and storage yards (maybe use “performance” somewhere)

- Cost-effective – eliminated need for soil replacement and drainage

- Highly sustainable – lowers carbon footprint by reducing amount of aggregate

- Improved pavement lifespan – minimal settlements and low maintenance over 13 years intensive use

- Excellent drainage – Neoloy reinforcement unaffected by moisture and climate

Stabilizing Saturated Peat Bogs, MEG Energy, Canada

A saturated Muskeg peat access road with extreme weather conditions was stabilized using Neoloy® Geocell reinforcement for all-weather access.

Read moreStabilizing Saturated Peat Bogs, MEG Energy, Canada

In 2012, MEG Energy’s oil sand mining operations at the Christina Lake complex in northern Alberta were expanding. Plans included new wells, processing, operations, storage, and treatment facilities, as well as constructing the roads needed to interconnect them. The existing soil in the area consisted of deep muskeg, 3-4 meters deep, with a moisture content greater than 800%. The client needed an access solution that would increase the bearing strength of the road base, provide a durable, all-weather road that was economically feasible, and could be completed before winter. Paradox Access Solutions proposed a design for the road using ToughCell® geocells. Utilizing locally available materials for infill, this innovative geosynthetic cellular confinement system increased the modulus of the existing subgrade and built a road, virtually over water, capable of supporting. 500,000 ESALs. The project delivered:

- Long life access to a remote facility

- Environmental benefits of a smaller footprint, less impact to the waterway and surrounding area

- Reduced cost by using local infill material

Approach

The saturated, organic soil in this region combined with harsh climate conditions made normal road-building difficult at best. Freezing in winter combined with heavy rains and poor drainage in summer typically impeded construction efforts almost year-round. Conventional construction methods necessitated the removal and replacement of the muskeg material. The cost of importing replacement infill along with the installation of drainage systems proved prohibitively expensive. Paradox Access Solutions provided a design utilizing two layers of Tough Cell® geocells. Instead of replacing the problematic muskeg, a layer of non-woven geotextile was placed directly over it. An initial layer of Tough Cell® was then installed over the geotextile and infilled with up to 1m of clean sand from a nearby borrow pit.

Construction

Paradox Access experts designed a reinforced road using one to three layers of Neoloy (Category-D tensile strength >22 kN/m) depending on the saturation level. The existing peat subgrade was covered with geotextiles for drainage and to prevent further mixing with the Neoloy layers.

The Neoloy Geocells were infilled with sand from locally available borrow pits and compacted. The strong hoop strength of the cells creates a “beam effect”, or semi-rigid mattress. This effect distributes vertical loads widely, reduces stress and settlement and extends the road life. The capping wearing course layer was filled with a thin layer of crushed gravel.

The end result was a reliable road that MEG Energy’s heavy rigs and other construction equipment could easily traverse.

Benefits

- Engineered solution – beam effect for increased bearing capacity and heavy trafficking

- Reliable performance – high tensile strength with long-term performance in extreme temperatures

- Sustainable solution – used local sand for infill and for structural reinforcement

- Fast, all-weather construction – rain and weather do not impede construction

- Drainage solution – all-weather use road in saturated soils and harsh climate

- Economical solution – use locally available sand, minimizes hauling and use of aggregate, quick construction

Video about using Neoloy® Tough Cell solution in extreme soil conditions

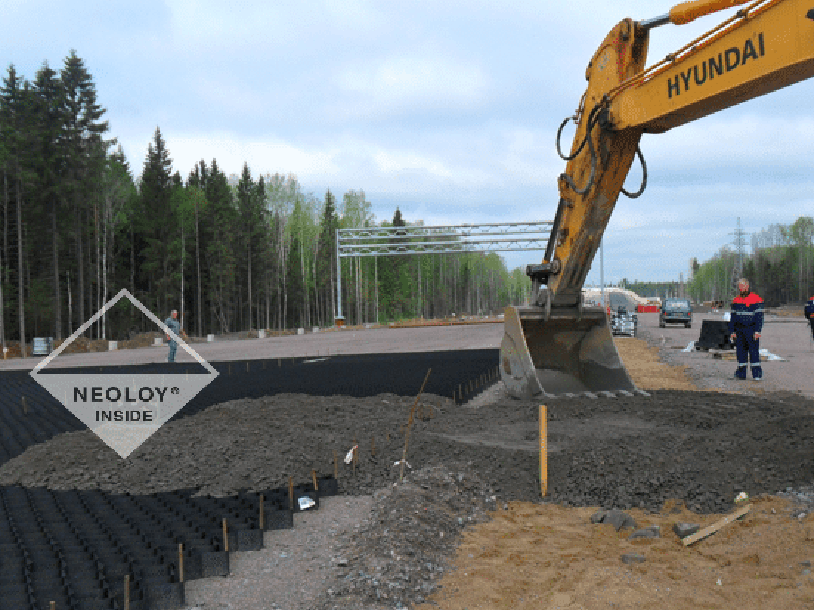

Building Highways on Sand – St. Petersburg, Russia

Neoloy® Geocells double the lifespan of highway using locally available sandy soil.

Read moreBuilding Highways on Sand – St. Petersburg, Russia

Challenge

The Western High-Speed Diameter Road (WHSD) is a 40 km North-South 4-8 lane motorway built to relieve congestion in St. Petersburg. It was the first urban high-speed toll road in Russia, with a planned traffic capacity of 1,000,000 vehicles monthly.

The original plan for the 26 km northern section called for a conventional pavement design on top of a road embankment and 1.0m thick working platform of sandy soil. This was comprised of a 70 mm subbase layer, 410 mm thick granular base layer and a 230 mm thick asphalt layer.

Neoloy Solution – Verification

An alternative design was presented to the NHC consortium responsible for the project, and a proof of concept project was implemented on a section of the A-118 Motorway. Based on Neoloy® Geocells, the goal of the design was to replace the expensive imported granular materials with locally available infill..

Stress monitoring by cyclical plate load tests (Russian standard: GOST 20276-99) of pre-installed pressure cells on sand subgrade verified that the Neoloy Geocell design improves the granular subbase modulus by a factor of 2.45. It also reduced vertical stress by ~50% and allowed a 13% reduction in asphalt thickness.

The demonstration project convinced the project’s commercial and technical experts to adopt and implement the Neoloy Geocell based design for the WHSD road project.

Why Neoloy

The Neoloy Geocell is a 3D mechanical stabilization technology which stiffens the confined layer. The unique properties – high dynamic stiffness, creep resistance and tensile strength – of the Neoloy novel polymeric alloy (NPA) enable the following design benefits:

- Increased modulus of granular layer (2.45x)

- Decrease in accumulated plastic strain in lower granular layers

- Lower tensile strain at bottom of asphalt layer leads to lower fatigue, higher design life (x47%)

- The Neoloy Geocells also reduce vertical stress by 50% with a significant decrease in the pavement thickness, while improving traffic capacity and pavement design-life.

UNOPS Chose Neoloy Geocells for Rural Road Stabilization

Neoloy® Geocells selected for reliable soil stabilization in South Sudan for long-term road infrastructure.

Read moreUNOPS Chose Neoloy Geocells for Rural Road Stabilization

Challenge – Creating a Reliable Lifeline for the Neediest

One of the least developed countries in the world, the new country of South Sudan faces enormous challenges. Large parts of the country lack basic road infrastructure, which severely impacts all aspects of life: from farming to economic opportunities, the perilous political-security situation, and a mounting refugee and food crisis. One vital strategy to address the chronic food insecurity, improve livelihoods and stimulate rural development is to improve the rural road infrastructure and provide access to markets. This would also enable critical aid to get in to those in need.

Neoloy Geocells – Best Road Performance Achieved Using Locally Available Resources

The United Nations Office of Project Services (UNOPS) worked with the Engineering firm of WSP|Parsons Brinckerhoff to provide an optimized pavement design for 225 km of roads in four regions. Conditions included poor subgrade, high traffic loading, and a lack of quality aggregate.

The solution was to build permanent roads with guaranteed long-term performance. This was not just another engineering challenge – it was literally creating a new lifeline for the country. After extensive investigations, WSP proposed the only fast, strong, durable and cost effective solution Neoloy Geocells. UNOPS then submitted the proposed solution for an independent engineering evaluation by ARUP Engineering Consultants to validate the design.

Engineering Design Assumptions Confirmed: Only Neoloy Geocell Provides Long-Term Stabilization For Permanent Roads

The bid specifications for the geocells issued by UNOPS were based on the following design considerations:

- Mechanistic design analysis

- Use of low quality infill material

- Overall stiffness required for expected stresses and strains

- Limited allowable creep for pavement life cycle

PRS was awarded the UNOPS bid for the the Supply and Delivery of Neoloy or approved equivalent for the manufacturer and delivery of 1½ million sqm of geocells within 16 weeks. Neoloy is the only geocell that met the project requirements for elastic stiffness, creep resistance and tensile strength.

The road design includes a wearing course, a formation level and in-situ material roadbed. The Neoloy Geocells are incorporated in the wearing course with significant overfill. The road is basically constructed from sand, with the higher quality sandy-gravel infill limited to the wearing course.

Key Benefits

- Low Cost – 50% Cost Savings Compared to Conventional Design

- Fast – 35% Reduction in Construction Time

- Better Road Performance, comparing to any other solution tested

- Sustainable Objectives Achieved

- Improving People’s Lives

Highway Case Studies in Poland

Paved service road in Poland with poor load-bearing capacity was upgraded by Neoloy®Geocells, drastically reducing pavement thickness and costs. Costs Reduced by 30% on Paved Service Road

Read moreHighway Case Studies in Poland

Poland is at an important crossroads in the European Union due to its physical location and its developing economy.Signifcant investments are being made by the government and the EU to upgrade the Polish highway system, and a large number of international engineering and contracting firms have ofces and representation in Poland.

In the feld of geosynthetics, there is widespread awareness, acceptance and accreditation of the PRS Neoloy Cellular Confnement System. Neoloy is a well known brand name in the professional academic, contractor and civil engineering community for to its outstanding properties and performance.

Costs Reduced by 30% on Paved Service Road

The S22 upgrade of 28.8 km of the national express road between Elblag and Grzechotki on the northern border of Poland included a service road for heavy construction vehicles. Much of the route was over clay soil with a poor load-bearing capacity (30-40 MPa). Neoloy Geocells were tested and selected by MSF-TGA engineers to meet their requirements for a 140 MPa load bearing capacity.

20 cm Neoloy Geocells were deployed with sandy soil infill, overfilled by 5 cm of sand and 10 cm of recycled concrete construction waste and 6 cm of asphalt. The reinforced road successfully supported the traffic of heavy construction and haul vehicles in all weather conditions. The temporary section was cost-effective, installed quickly, and removed without damage to the environment.

Benefits

- Reduced the structural pavement thickness by as much as 44%, and lower project costs by 30%

- Inexpensive, fast and easy installation

- Increased load-bearing capacity

- Reduced road repairs and maintenance

- Minimal on-site environmental impact

More objects from Poland: PDF

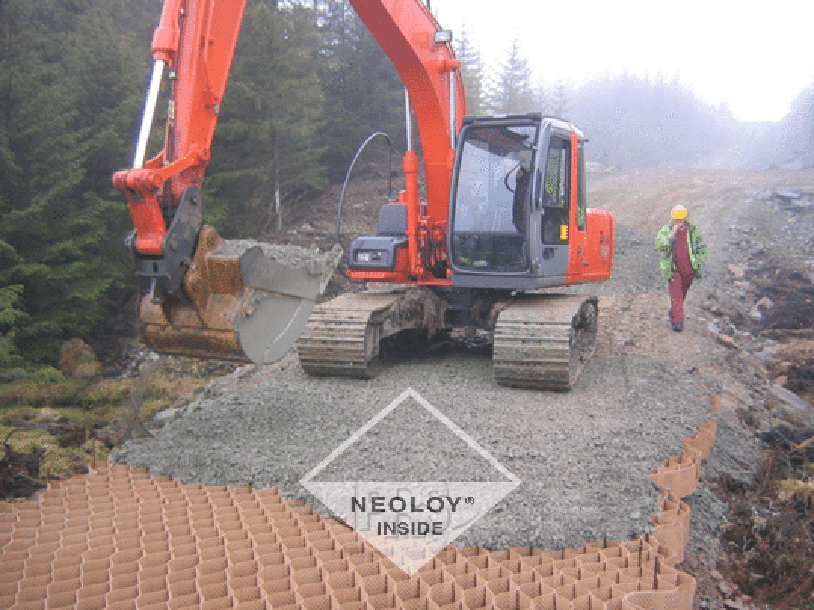

Logging Road for Irish Forestry over deep saturated peat, Ireland

Neoloy® Geocells provide foresters with a novel solution that is revolutionizing the way forestry roads are built and timber harvested.

Read moreLogging Road for Irish Forestry over deep saturated peat, Ireland

The Challenge

Coillte Forestry company required a logging road over deep upland-peat in the in a remote mountainous area of South West Ireland. The existing peat has poor bearing capacity and very saturated, uncapable of handling the 45-tonne vehicles required for timber harvesting.

The conventional solution is a “corduroy road” a portion of the tree harvest is sacrificed, cut and laid perpendicular across the road for a working platform. This is filled with layers of stone in depths of up to 1.2 metres. This method means a loss of part of the harvest as well as a limited construction pace of about 40-50 linear meters per day and requires availability of reasonable quality stone of suitable size to achieve some interlock.

PRS Neoloy Solution

PRS Neoloy Geocells enabled Coillte to build a cost-effective access road across this area using locally dug, poor-quality stone, which could support heavy loading and frequent passes for a 40-year lifespan!

The Neoloy solution was for a single layer of 200 mm height Neoloy Geocells with a 50 mm overfill directly over a non-woven geotextile separation layer. No subgrade excavation was required. Construction proceeded smoothly in a continuous stream. The customer reported complete satisfaction with the road performance several years after construction.

Why Neoloy

Neoloy Geocells provided a completely innovative solution to a forestry company that built logging roads the same way for decades. The Neoloy Geocell was chosen due to its resistance to fatigue and rutting, even over the softest of soils – and guaranteed to continue its performance with permanent degradation for the 40 year design life of the road.

The solution was developed by PRS Engineering in consultation with the customers technical staff to provide an optimized and cost-effective solution for their unique road engineering requirements.

Benefits

- 500% increase in construction speed over traditional methods

- No loss of harvest crop to facilitate construction

- Reduction in the volume & scale of excavation from local borrow-pits due to the smaller quantity of stone required

- Unique Neoloy novel polymer composition mitigates environmental impact, and presents no hazard to natural fora & fauna or watercourses.

- Ability to use poor quality in-fll materials – local rounded gravels normally considered unsuitable can be used for fll

Reinforced RAP for Street Rehabilitation, Colombia

Neoloy®Geocells provided ideal solution to reinforce recycled asphalt pavement, significantly increasing modulus, saving costs.

Read moreReinforced RAP for Street Rehabilitation, Colombia

The Institute of Urban Development (IDU) of Bogota decided to rehabilitate run-down road infrastructure. The plan called for reclamation of large existing stockpiles of waste asphalt collected from resurfacing programs to repave the streets. However, the low strength of the reclaimed asphalt (200-300 MPa) required processing to improve its modulus (to 900 MPa) for use in conventional pavement design.

After consulting with the geosynthetic experts at Pavco Geosystems and PRS engineers on-site, Incoplan SA engineering consultants were convinced of the suitability of cellular confinement systems for RAP, despite any prior familiarity with geocells.

Although permanent deformation or rutting is one of the concerns in the use of RAP as a base course due to creep deformation, Incoplan engineers learned that the lateral confinement provided by Neoloy Geocells to granular materials would significantly reduce creep deformation of RAP. In particular, the engineers were impressed by the high-modulus performance of the Neoloy Geocell, based on novel polymeric alloy, which has been tested and proven in studies and field trials around the world.

Conventional Solution

Conventional use of RAP required processing with bitumen to improve strength in reclaiming the existing milled asphalt. This increased hauling costs to the asphalt processing facility, as well as indirect costs, such as pollutants, energy and bitumen used in the processing.

The conventional pavement design proposed 4 layers of 15 cm processed RAP for a combined 60 cm base/subbase, with a new asphaltic concrete wearing course of 8.4 cm thickness.

However, tests comparing unconfined vs. PRS-Neoloy-confined RAP in the base of pavements carried out under Dr. Jie Han of the University of Kansas show that the unconfined RAP is subject to significantly higher creep deformation resulting in permanent surface deformation and rutting.

Neoloy Geocell Solution

Unprocessed RAP was used as infill in the Neoloy Geocell reinforced base layer, comprised of 12.5 cm height Neoloy 330 size cell plus 5-8 cm overfill (depending on each street alignment). The same unprocessed RAP was also used for the 30 cm subbase infill as well. The wearing course was a new 8.4 cm asphalt layer.

The Neoloy Geocell reinforcement mechanism (Modulus Improvement Factor – MIF) increased the existing low strength infill from 200-300 MPa to 1000 MPa modulus for the existing milled asphalt stock RAP infill without processing.

These savings enabled the contractor to increase the number of streets in the rehabilitation. The improved modulus of RAP also enabled a reduction in the overall thickness of the pavement structure. In addition to the 10% net savings, the project construction was faster as excavation, infill and compacting were all reduced.

The municipal road authority, the engineering consultants and the contractor were all so satisfied that the program is being extended to another 50 streets.

Benefits

- ~40% net cost savings in project

- Eliminate hauling to/from processing facility

- Less excavationon

- Reduced layer thickness

- Increase in the number of roads to be rehabilitated, due to the reduced RAP used

- Faster installation and reduced man- and equipment hours

- Innovative sustainable technology

- Long lifespan

Reinforced Base in Highway, Israel

Sustainable highway reinforcement with Neoloy®Geocells on section of Israel’s Highway 6 reduced asphalt layer by 23%, infill by 37%

Read moreReinforced Base in Highway, Israel

The Challenge

The Cross Israel Highway (Highway 6) is a 140 km national electronic toll road traversing the country’s long North-South corridor. Highway 6 is a DBOT (Design, Built, Operate, Transfer) project built by AECON Canada’s largest construction and infrastructure development company, at a cost of $1.4 billion. The Highway 6 concessionaire, Derech Eretz Group, needed to add a third lane in each direction in response to increased traffic intensity, and decided to test the Neoloy Geocell cellular confinement system in pavement sections. The goal was to demonstrate how Neoloy could be integrated in a cost-efficient design by reducing the cost of infill and asphalt while maintaining long-term performance, within the following guidelines:

- Use standard design methodology and meet national standards

- Pavement thickness should align to the existing elevation

- Reduce overall asphalt layer thickness

- Replace base infill with less expensive granular subbase material

Neoloy Geocell Design

While the unreinforced conventional design for the Highway 6 pavement consists of: 200 mm asphalt, 200 mm crushed stone base and 170 mm subbase (670 mm total thickness), the alternative design with Neoloy Geocells included two key improvements:

- Replace the crushed stone base infill layer with lower quality granular infill (subbase class A); it was used for the base (240 mm) and subbase (170 mm) layers – TOTAL INFILL SAVINGS = 37%.

- Reduce base of asphalt layer from 100 to 60 mm – TOTAL ASPHALT LAYER REDUCTION = 23%.

Neoloy 330 small size 140 mm height geocells (4 m wide sections) were installed in the base layer. The Neoloy Geocells serve as a reinforcing inter-layer in the upper pavement directly under the asphalt (contrary to conventional geocell use in the subgrade). This maximizes the 3D reinforcement mechanism, thereby increasing the pavement structure bearing capacity and load distribution.

The road design was based on the empirical-mechanistic methodology and Flex-Design pavement design software. The use of Neoloy Geocells resulted in a 2.7x higher elastic modulus for each pavement layer.

Access Road for Wind Farm Through Peat Bogs, Scotland

Neoloy®Geocells were deployed to construct a wind farm access road over a Scottish peat bog, ultimately reducing project costs by 72%.

Read moreAccess Road for Wind Farm Through Peat Bogs, Scotland

Challenge

An access road was required for transporting a wind-turbine generator to a construction site and for installing power lines within a Scottish nature reserve. The site was in mountainous terrain, while the access road crossed peat bogs. Local nature authorities required a sustainable solution with minimal environmental impact, including dismantling of the road to restore the area to its previous natural state.

Conventional Approach

The original plan required several 60-80 cm thick granular infill layers; however, this solution was expensive, complicated and irreversible.

Neoloy Geocell Solution

The use of Neoloy Geocells was proposed for fortifying road segments running over peat. The client decided to conduct a test of the performance of Neoloy Geocells on muddy soil, to verify: minimal environmental damage during installation, sufficient load-bearing capacity, and test its removal. Neoloy successfully passed the test and was selected for project implementation. The client deployed Neoloy Geocells utilizing locally won borrow pit soils for infill.

Benefits

- Significant reduction in required granular infill thickness to 20 cm, saving approximately 0.6m of compacted granular infill / sqm

- Significantly shortened timetable

- 72% reduction in overall project costs

- Minimized environmental footprint in natural sensitive area

Using Neoloy Geocells the required granular infill was reduced by as much as 120,000 cubic meters, which greatly reduced project costs and minimized the need for granular infill excavation that damages the environment. The road was easily dismantled and the land returned to its natural state.