Durable Pavement For UK Army & Afghan Population

Neoloy®Geocells were used to construct new, safe and durable pavement for UK Army operations and Afghan civilian reconstruction.

Read moreDurable Pavement For UK Army & Afghan Population

“Neoloy is the key foundation to the project. The effect Route Trident is having on the local population is already quite astonishing. In the short time since its completion, a market and even a doctor’s surgery have sprung up along its route.”– Major Adam Foley (Engineer), Officer Commanding, 64 Headquarters & Support Squadron, Royal Engineers, British Army

Although British forces conducted successful military operations in the Helmand Province in Afghanistan in late 2009, insurgent activity continued to impede the movement for both local Afghans and troops along the only trafficable road through the area. The patrol bases were dependent upon air-dropped supplies, while civilian reconstruction efforts were impeded.

In order to stabilize the region, a new and secure route had to be created. This route had to connect the army patrol bases as well as provide safe and reliable transport for the local civilian population.

The British Army Royal Engineers, responsible for combat support and the development of critical infrastructure for the civilian population, were assigned the mission. They faced three key challenges according to Major Adam Foley (Eng.) who led the project. First the total budget was ₤3.5 million, in an area where the price of aggregate was exorbitantly high due to hostilities ($250-650 per cubic meter), thereby limiting its use. Second was how to cross a 300m-wide wadi (valley) and irrigation system. Last but not least was the concern for security along the route during construction and subsequent use.

The Neoloy Geocell confinement system was chosen by the Royal Engineers after conducting trials with various infill materials and road make-ups.

Construction Under Fire

Code named Route TRIDENT, the 7.6 km long road was designed and constructed by the British Army Royal Engineers 28 Regiment. Specialist Engineer road builders, including sappers and support forces and some 90 Afghan local vehicle operators and laborers were deployed in “construction battle groups”, which were subject to continuous sniper fire and improvised explosive devices (IEDs).

The Neoloy Geocell road was designed for durability under heavy vehicles and harsh weather. The strong Neoloy based 3D confinement in the road base was infilled with locally dug soil (at zero cost). The composite system behaves like a semi-rigid beam, which distributes loads laterally and reduces sub-grade stress. Therefore aggregate was only required for the wearing course. Foley stated that Neoloy Geocells allowed for a 75% reduction in the quantity of aggregate, and a reduction in the cost per meter by 2/3 compared to a normal unbound aggregate road.

Exceeding Expectations

On March 10th the first military convoy passed down route Trident without encountering ambushes. A trip which usually took 36 hours to complete, took less than 30 minutes! Foley said that “the convoy moved unhindered and unopposed along the new road in just 30 minutes proving its concept to be an undeniable success.”

The road passes through desert sand as well as farmer’s irrigated fields and canals, critical to the local agriculture. Large box culverts and a “floating” road comprised of Neoloy Geocells were used to “forge” exceptionally waterlogged ground, which was previously impassable to vehicles. “The effect Route Trident is having on the local population along its length is already quite astounding,” says Foley. Shortly after completion, shops and markets sprung up along the route, while a doctor’s office and school are being built.

The design and construction techniques developed on Route Trident are being used the Royal Engineers across Helmand.

BENEFITS

- Simple logistics and quick installment

- Reinforce local soils with high bearing capacity

- Improve structural strength while reducing required pavement thickness

- Deployed in any climate or environment

- 3D honeycombed structure prevents placement of IEDs

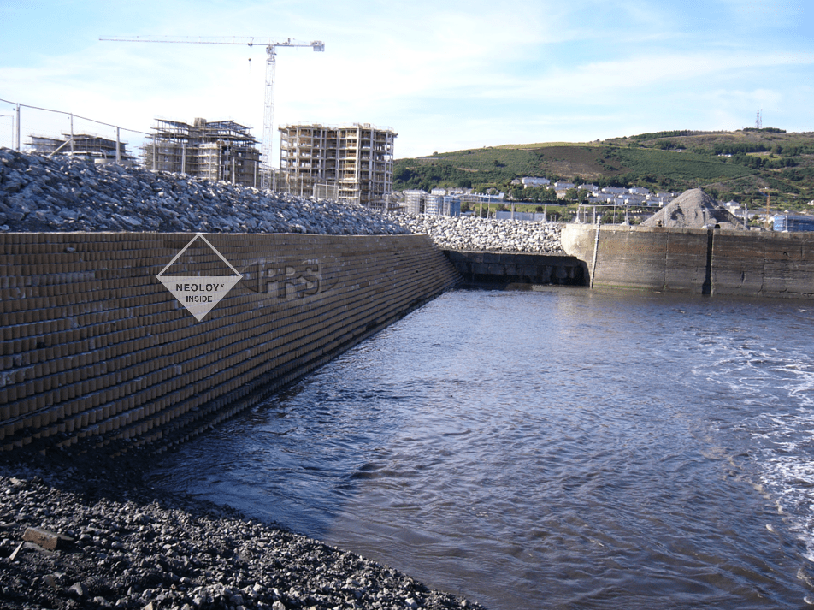

Sea Wall for Canal, Swansea, Wales (Reinforced Retaining Wall)

When high tides and coastal erosion threatened flooding, a new seawall reinforced by Neoloy®Geocells provided a durable and aesthetic solution.

Read moreSea Wall for Canal, Swansea, Wales (Reinforced Retaining Wall)

Challenge

The client needed to create a protective wall to prevent flooding in an old canal, due to high tides and coastal erosion. In addition, the solution had to withstand wave action as well as corrosion from sea water.

Conventional Solution

One solution considered was using iron netting filled with rocks, which had failed previously due to corrosion caused by sea water. Another option was to build a reinforced concrete wall with prefabricated elements.

Neoloy Geocell Solution

The chosen solution involved building a reinforced retaining wall made up of horizontal layers of 200mm high Neoloy Geocell. The front cells were filled with concrete, while the rest of the cells were filled with granular fill of lower quality.

Benefits

- Substantial time savings of about 50% by constructing the solution in a single step

- Enhanced durability and flexibility of the reinforced wall

- Aesthetic appearance that blends into the landscape

- Neoloy was successfully used to build a durable yet aesthetic wall that saved the client significant time and money.

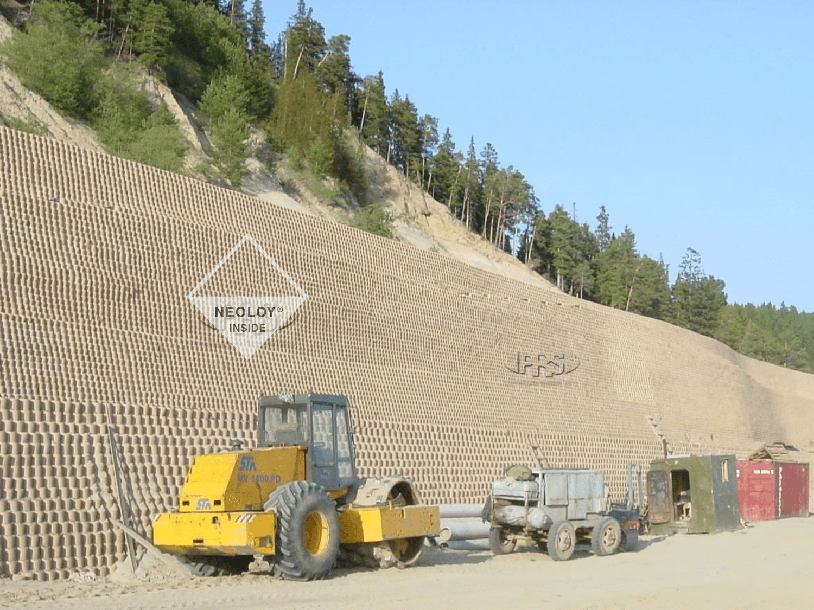

60+m High Retaining Wall for Unstable Mountain, Khanty-Mansiysk, Russia

Neoloy Geocells were utilized in order to stabilize a mountain slope in Russia prone to landslides, helping reinforce a huge 60m high retaining wall.

Read more60+m High Retaining Wall for Unstable Mountain, Khanty-Mansiysk, Russia

Challenge

A wooded sandstone mountain in the district of Khanty-Mansiysk in Russia was experiencing landslides due to erosion and freezing and thawing cycles. The landslides also blocked the access road to the city, caused drainage and flooding problems, and marred the landscape at the entrance to the city. A retaining wall reaching up to 60 meters was needed.

Conventional Solution

One possibility was to build a reinforced concrete retaining wall with a deep foundation, at very great heights. This solution required suitable base materials and very deep excavation work. This solution was not chosen due to the area’s problematic soil and ground water. Another possibility was to spray concrete together with very expensive ground anchors due to the huge height of the wall, but this solution lacked long-term strength.

Neoloy Geocell Solution

The slope was stabilized, up to a height of 60 meters above the base of the hill, by a retaining wall built with horizontal layers of 200 mm high Neoloy Geocell. A complex system of heavy wall and slope soil stabilization (the back filling) was installed, combined with a front geocell retention wall that provided additional support considering the wall’s huge dimensions. Geogrids were used for horizontal reinforcement. The project scope involved about 2 million square meters of retention wall.

Benefits

- Superior stability without the need for adding foundation materials

- Rapid installation in comparison to the alternatives

- Substantial project cost savings – the use of local sand, instead of stone or concrete that were not available at the site, saved millions of dollars

- Enhanced flexibility of the retaining wall enabled it to withstand the ground’s seismic movement

- The client successfully implemented a highly stable infrastructure project of massive proportions while enjoying significant time and cost savings.

Bioswale Stormwater Management, Czech Republic

The developers of a new hypermarket used Neoloy®Geocells for bioswale storm management, drastically reducing construction and transport costs.

Read moreBioswale Stormwater Management, Czech Republic

Challenge

The developers of a new hypermarket and the planning department of Ostrava decided to create a bioswale to improve the treatment of storm runoff from the built area and parking lot. A bioswale is a shallow vegetated depression that treats storm water locally by filtering out contaminants through the soil. The design called for a 7000 m2 bioswale to slow and clean storm water runoff from the building’s parking lot and grounds instead of a traditional storm drain system. A green solution was desired to integrate with the adjacent landscape, which includes a large wooded area and local bicycle paths.

The original plan called for revetment slopes protected with Articulated Concrete Blocks (ACB). However, the cost, logistics and installation for this type of solution were very high. An individual ACB unit weighs 34 kg; a single pallet of 40 units weighs 1360 kg but covers less than 10m2. The entire project would require some million kg of blocks. The contractor was interested in finding a more efficient, economic and environmental solution.

Conventional Solution

ACB’s provide effective revetment-slope protection but at a high cost. In addition to a per m2 cost 2x greater than Neoloy Geocell, their heavy weight makes logistics and installation even more expensive and complicated.

Depending on the configuration, the weight of one average ACB block is more than an entire folded section of Neoloy (~15 kg). The same 15 kg Neoloy Geocell section can provide coverage for an area of ~30 m2, whereas more than 100 ACB block units at > 2000 kg are required to cover the same area. This has enormous ramifications on transport, handling (requires mechanical equipment) and construction, making the project longer and more expensive.

Neoloy Geocell Solution

The use of Neoloy Geocell eliminates the complicated logistics and installation associated with ACB’s. The total Neoloy Geocell shipment of folded 356 cell size 100 mm height sections arrived on site in one truck (9000 kg). Installation was simple and fast. The sections were unfolded and installed manually without the need for mechanical handling equipment.

The sections were stapled together, secured at the crest with stakes and opened downward. No geotextile was used to maximize runoff water percolation and filtration. Tendons and stakes were used to bind the system to the slope soil. Locally available granular topsoil was used for infill and a hardy species of grass turf was planted by seeding.

Benefits

- Low-cost: 50% lower initial cost than ACB system, in addition to very significantly lower transport, handling, equipment and manpower requirements.

- Fast Installation: Simple logistics, light-weight sections, fast deployment.

- Material: Long-term resistance to creep, oxidation, temperature extremes, UV light.

- Hydrological: Stable protection system against sliding, tractive and uplift forces from water flow

- Environmental: Excellent micro-environment for turf growth and prevention of erosive forces.

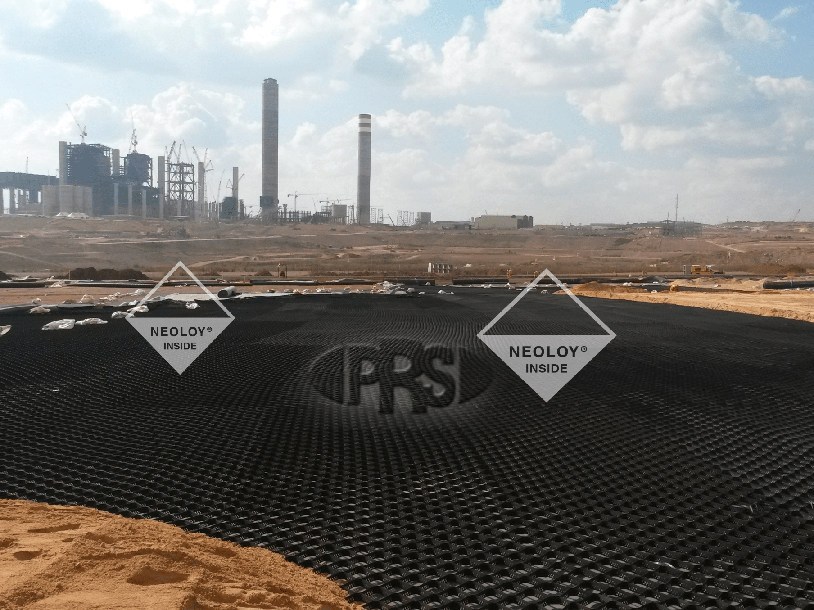

Landfill Protection | Protecting Coal Ash Landfill, South Africa

Reinforce Geomembrane for Fly Ash Waste Containment, Neoloy® Geocells provides durable, long-term protection for landfill geomembrane and leak detection system.

Read moreLandfill Protection | Protecting Coal Ash Landfill, South Africa

The Challenge

Eskom’s Kusile new power station near Pretoria and Johannesburg will be the 4th largest coal-fired power station in the world when fully operational. As a bi-product, Kusile also produces hundreds of thousands of tons of coal waste (also referred to as fly ash or coal ash), which requires disposal in protected landfill dumps with enough storage capacity to last 50 to 60 years. As a potential hazardous pollutant to groundwater, the coal waste lagoons are comprised of a system of liners and monitoring systems to prevent seepage into the environment.

A sand layer is an integral part of the containment solution to detect and contain any leaks. However, the sand must be mechanically confined on slopes in order to maintain the integrity of the layer. The solution also required that the bed or ground of the dump be reinforced sufficiently to protect the sand as well as the geomembrane layers from truck traffic.

Conventional Solution

A solution such as reinforced concrete would require expensive transportation of imported materials. In addition, a long-lasting, durable base over sand would need significant maintenance, as protection against pollution must be guaranteed. This would require close monitoring and high cost.

Neoloy Geocells Solution

ESKOM designed a durable composite liner system to ensure the safety of the surrounding ground water for many years to come.This multi-tiered composite liner system for the fly ash dump consisted of seven layers, including a 100 mm sand layer into which, PRS Neoloy Geocells were placed.

Neoloy is a high-performance novel polymeric alloy (NPA) with high stiffness, tensile strength and creep resistance. These parameters enable the Neoloy Geocell to sustain high loads over time without deformation. This guarantees the durability of the protection system for the long lifespan of the landfill.

The cellular confinement properties of Neoloy’s geocells prevent movement of the sand layer during continuous trafficking of heavy vehicles on the ash dump’s access road. Over 1/4 million m2 of Neoloy Geocell 50 m height were used at the site.

Benefits

- Cost-effective – reduces construction and maintenance costs

- Simple logistics and installation – folded sections easy to ship and fast to install

- Flexible system – accommodates subgrade movement and prevents cracking

- Long design life – unique parameters suitable to long-term design life of landfill

Fast, Cost-effective Neoloy® Irrigation Channels, Vietnam

Neoloy® Geocells were chosen to provide irrigation channels, which are installed quickly, increase capacity and reduce deterioration.

Read moreFast, Cost-effective Neoloy® Irrigation Channels, Vietnam

Challenge

While Vietnam has made tremendous gains in its agricultural sector (currently the 4th largest exporter of rice in the world, 2016), investments in water management systems are critical to sustain growth, productivity and diversification.

Much of Vietnam’s irrigation and drainage systems need modernization to increase capacity and operational efficiency, and to stop deterioration, which leads to damage to lower end distribution systems, especially earth-lined channels.

One critical factor is the time it takes for the construction of the channels. This is critical as this must be undertaken during the short dry winter to prevent flooding and to minimize downtime for the irrigation system.

The Ministry of Agriculture and Rural Development (MARD) is making huge investments in improving the country’s water management infrastructure, including the adoption of innovative new technologies – and they investigated the Neoloy Geocell solution.

Conventional Solution

Conventional irrigation channels are made of earth lined walls. These suffer from continuous erosive forces, as well as a lack of maintenance, resulting in inefficient flows for both irrigation drainage and supply. Concrete channels are the preferred solution but typical form construction for the concrete are labor and resource-intensive, time-consuming, and more expensive.

Neoloy Geocell Solution

Neoloy was selected by MARD as the fastest, most reliable and cost-effective for channel protection. The trapezoidal channel dimensions were: 3m high walls at > 41° angles; the channel bed was 3.5m bed wide; the slope of the channel bed was s=0.03%; while the water flow velocity was designed for v=3m/s.

356-50 high Neoloy Geocells were used as they not only provide best quality control results for poured concrete. This size also provides a maximum reinforcement factor, such that the quantity of concrete can be reduced for even more cost savings. Fast construction was a key to this project. The channels were built during the dry winter months when farmers do not cultivate water intensive crops such as rice.

After clearing and compacting the slopes at the design dimensions and angles, fastened Neoloy sections were anchored to a 20 cm crest, and then spread out and over the channel, anchored at an average density of 4 x 4 cells.

Installation was fast about 100 m2 per day, undertaken by locally trained work crews. The 7 cm thick M200 concrete was poured into the Neoloy Geocells and levelled and smoothed. Hardening time was usually 28 days.

Benefits

- Easy logistics of folded sections

- 50% faster installation than any other method

- Locally trained work crews

- High reinforcement factor reduced concrete by 50%

- 35% cost savings

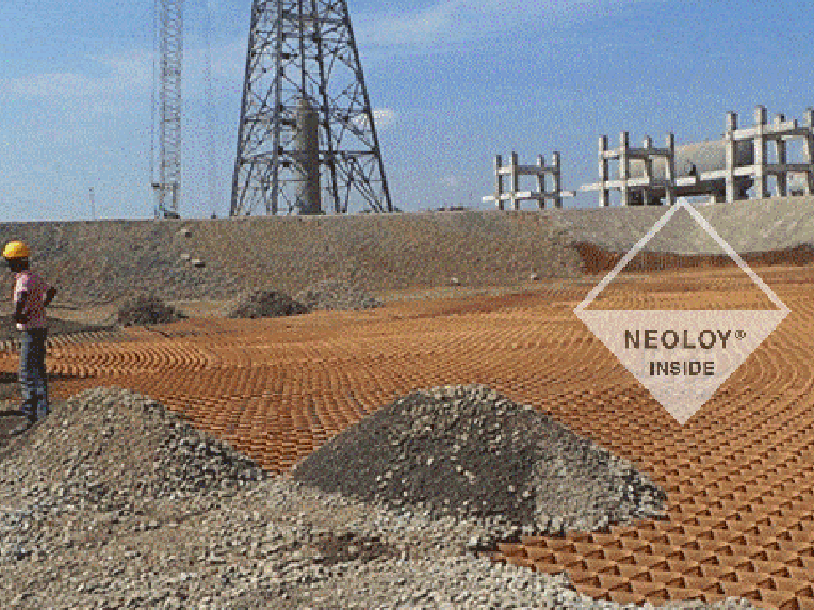

Foundation Stabilization for Geomembrane, India

Reservoir Geomembrane Protection Against Damage. Neoloy®Geocells provided the reservoir geomembrane protection required on a soft silty sand with a high water table, resulting in ground stabilization.

Read moreFoundation Stabilization for Geomembrane, India

The design of a new compression station for the Gujarat State Petroleum Corporation (GSPC) included a power station and four cooling ponds. The facility located in Mallavaram, Andhra Pradesh is part of GSPCs gas pipeline transmission network expansion.

However the native soil of the site was comprised of non-homogeneous soft silty sand with a high water table. The subgrade had non-uniform bearing capacity. Hydrostatic pressure from the water and the self-weight of the earthen embankments on this soil could cause significant differential settlement. This would lead to excessive stretching of the lining, potential damage and even failure of the reservoir.

A ground stabilization solution was needed to improve the bearing capacity of the pond beds, which would distribute stresses more uniformly and limit differential settlements. This was critical for reliable, long-term performance. The consulting firm, Engineering India Ltd (EIL), was tasked with coming up with a cost-effective foundation improvement solution for the ponds.

Conventional Solutions

Alternative solutions to create a uniform layer called for extensive subgrade replacement with a thick capping layer of quality aggregate. This solution was not cost-effective and does not deal with the high water table. Cement stabilization is too difficult to apply uniformly, its reliability over the long-term is questionable even in unsaturated conditions. Geogrids can not provide the same level of ground reinforcement and require imported higher cost aggregate.

Neoloy Geocell Solution

Neoloy Geocells were chosen to strengthen the reservoir foundations, thereby providing protection for the geomembrane from underneath it. This differs from the more common use of Neoloy Geocells, which are placed on top of the geomembrane to protect it, usually with concrete infill. The Neoloy layer on the pond subgrade distributes vertical pressures laterally, limits differential settlement and improves its bearing capacity.

150 mm high Neoloy Geocell was laid out over a non-woven geotextile and filled with 40 mm downsize aggregates. A layer of 50 mm aggregate and 50 mm sand was placed as a cushion between the Neoloy and the geomembrane. Two non-woven geotextiles were laid under and over the geomembrane for separation. The surface layer consisted of 150 mm thick concrete paving blocks set in 20 mm of cement mortar plaster on top of a 75 mm layer of sand.

Neoloy Geocells were also utilized on the slopes of the earthen embankments as well to maximize the geomembrane protection of the earthen embankments.

Benefits

- Fast installation – easy and fast all-weather installation.

- Cost-effective – lower cost than alternatives.

- Multiple use – same Neoloy used for base improvement and slope protection.

- Performance – guarantees long-term high bearing capacity of the reservoir bed.

- Flexible solution – tolerates minor ground movement without degradation or failure, including seismic activity.

Green Retaining Wall, Northern England

Quick And Green Retaining Wall Construction. In a residential project in Northern England, retaining wall construction using Neoloy® Geocells provided a strong, green and aesthetic solution to erosion.

Read moreGreen Retaining Wall, Northern England

Challenge

The developer of this residential project needed to stabilize a clay /sand stone slope to enable construction of adjacent apartment buildings (at distances as little as 1.2 m from the buildings). The soil suffered from erosion and poor bearing capacity. To gain residents’ approval, the solution had to be strong and aesthetic. Since the wall would be visible from many of the properties, residents demanded a green-faced solution to suit the surrounding park landscape requirements.

Conventional Solution

One solution considered involved constructing a reinforced concrete wall or crib wall, which did not suit the landscape and required large quantities of steel. Due to the proximity to the building, this solution was rejected.

Neoloy Geocell Solution

The developer installed a series of staggered Neoloy Geocell strips, infilled with local topsoil, to create a 6m tall, 276 m long retaining wall. Neoloy provided an easily built and aesthetic earth retention solution. The project’s fast installation time of only eight weeks reduced construction time by up to 30% and lowered overall costs.

Benefits

- Enhanced flexibility accommodating uneven surface contours

- Easy planting of vegetation in cells meeting demand for “green” solution

- Fast, easy installation requiring only minimal training

- Long-lasting, low-maintenance solution

Bridge Embankment Protection, Israel

Bridge foundation erosion control with Neoloy®Geocells gave sound protection for 15th century construction, with no environmental or aesthetic impact.

Read moreBridge Embankment Protection, Israel

The Challenge – Prevent Erosion While Bridge Still in Use

The bridge, a historical construction from the Mameluke period (15th century AD), is still used today for transport of light and heavy vehicles. Water flow from winter rains undermines its foundations and threatens its mechanical stability. The client needed to prevent the underneath foundation from erosion, while allowing continued use of the bridge – all with zero environmental and aesthetic impact.

Old Approach – Reinforced Concrete Slabs

A conventional approach is to install reinforced concrete slabs, which requires large cranes and complex logistics.

Neoloy Geocells Solution

The client deployed an array of 200 mm Neoloy Geocells infilled with concrete. Non-ferrous Neoloy Geocells provided a complete precast concrete-reinforced solution that was able to withstand strong water flows. The Neoloy Geocell structure maintained flexibility and strength, providing effective protection against hydro-static pressure.

Benefits

- 30% reduction in project costs by eliminating need for reinforced concrete slabs

- Flexible concrete-reinforced channel lining

- Easy, Inexpensive installation

- Environment – enhanced suitability with specific site conditions, including environmental and aesthetic requirements